Our means of production

Wire stock

Wire stock

Tooling workshop

Tooling workshop

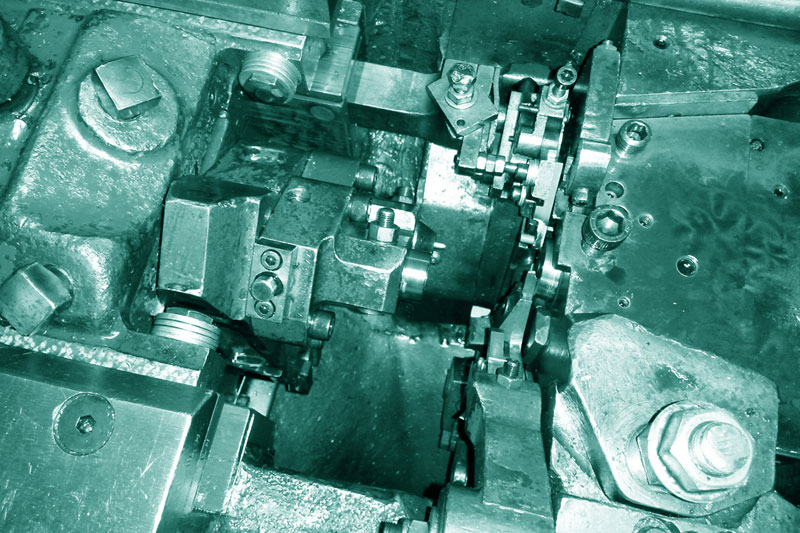

Cold forming workshop

Cold forming workshop

Packaging

Packaging

Our toolmakers machine, quench, grind and adjust the tools in accordance with the requirements expressed by the Design Department.

Once installed on one of our many horizontal presses (commonly known as cold forming machines) and adjusted by our specialists, the tool cuts and cold forms a metal wire billet at high speed so as to obtain the predefined part.

Production is 100% automatic and continuously inspected.

In order to complete your specifications, the cold formed parts are directed to various finishing operations:

- Rework (extrusion, pointing, drilling, boring, chamfering, bending, assembling, slitting, etc.)

- Heat treatment subcontracting (stress relief annealing, cl8.8 quenching, cl10.9 quenching, cl12.9 quenching, case hardening, QPQ, solution annealing, etc.)

- Surface treatment subcontracting (zinc plating, GEOMET coating, hot-dip galvanising, ALODINE 1200, nickel plating, rilsanisation, anodising, brass plating, oiling, etc.)

- Cleaning (tumbling, surface cleaning, spin drying, fine polishing, etc.)

- Packaging in accordance with our standard or your requirements